Our modern turbine control HCU 4.0

Full control with HyCON

The DNA of an economically operating hydropower plant is a smart and automated control system with high-quality components.

With more than 20 years of experience in the field of hydropower control systems, we have developed a turbine control system that meets all the technical requirements of a modern hydropower control system and is easy to operate and low-maintenance at the same time

The turbine control HCU 4.0 is suitable for all turbine types up to 1 MW.

Each control can be individually configured to your requirements to achieve the optimum energy production of your plant.

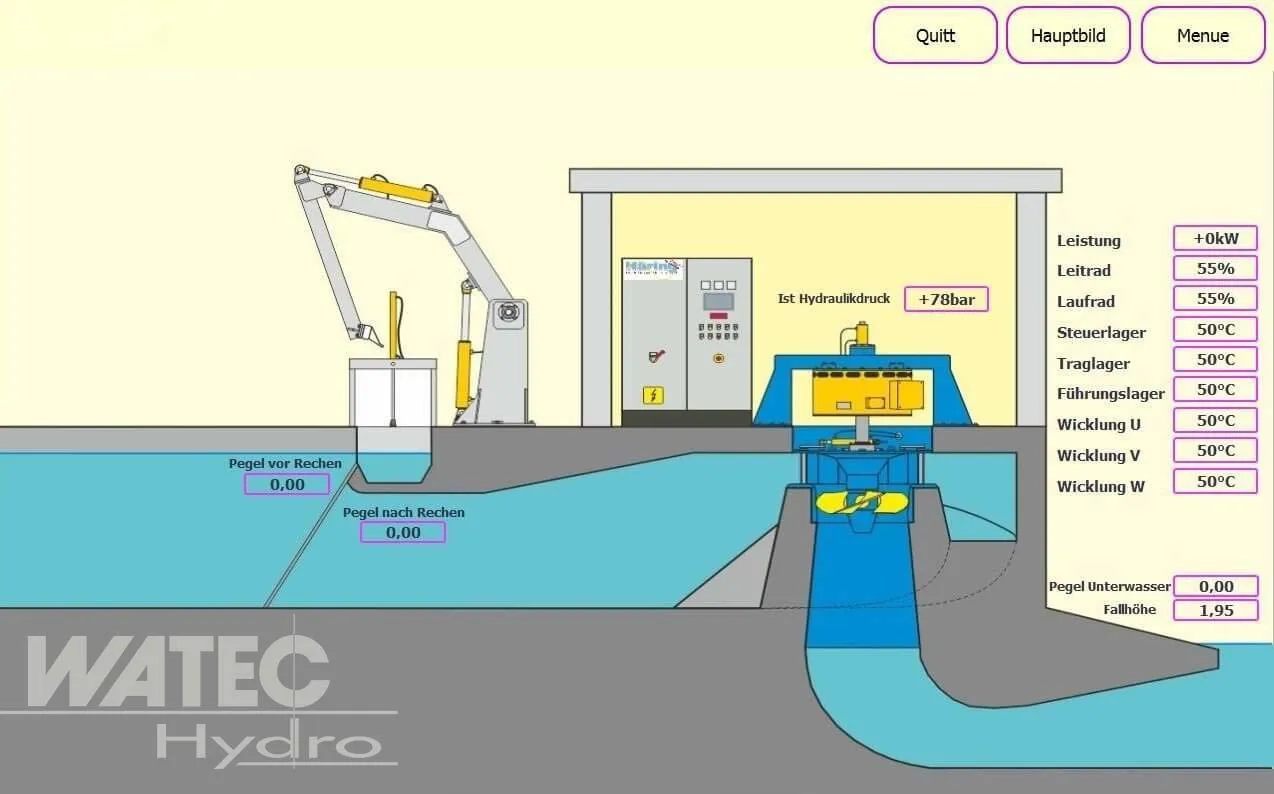

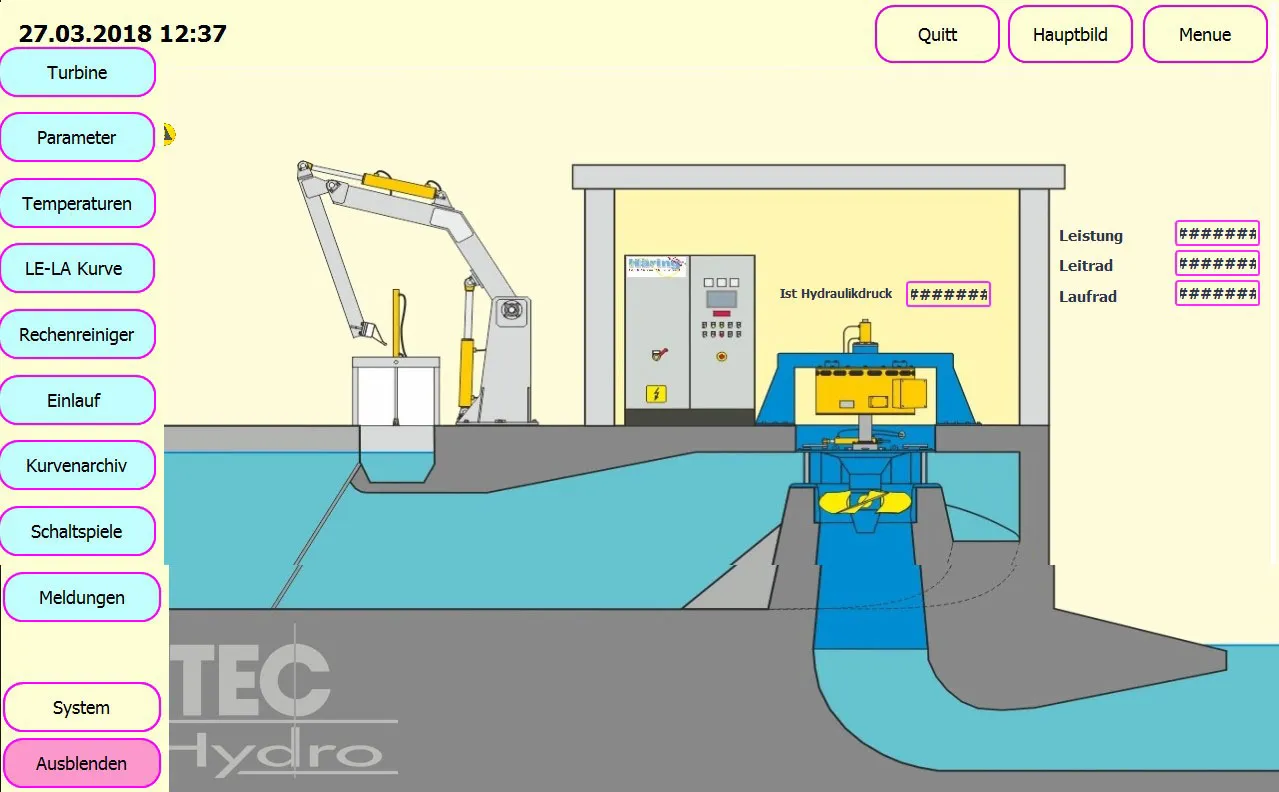

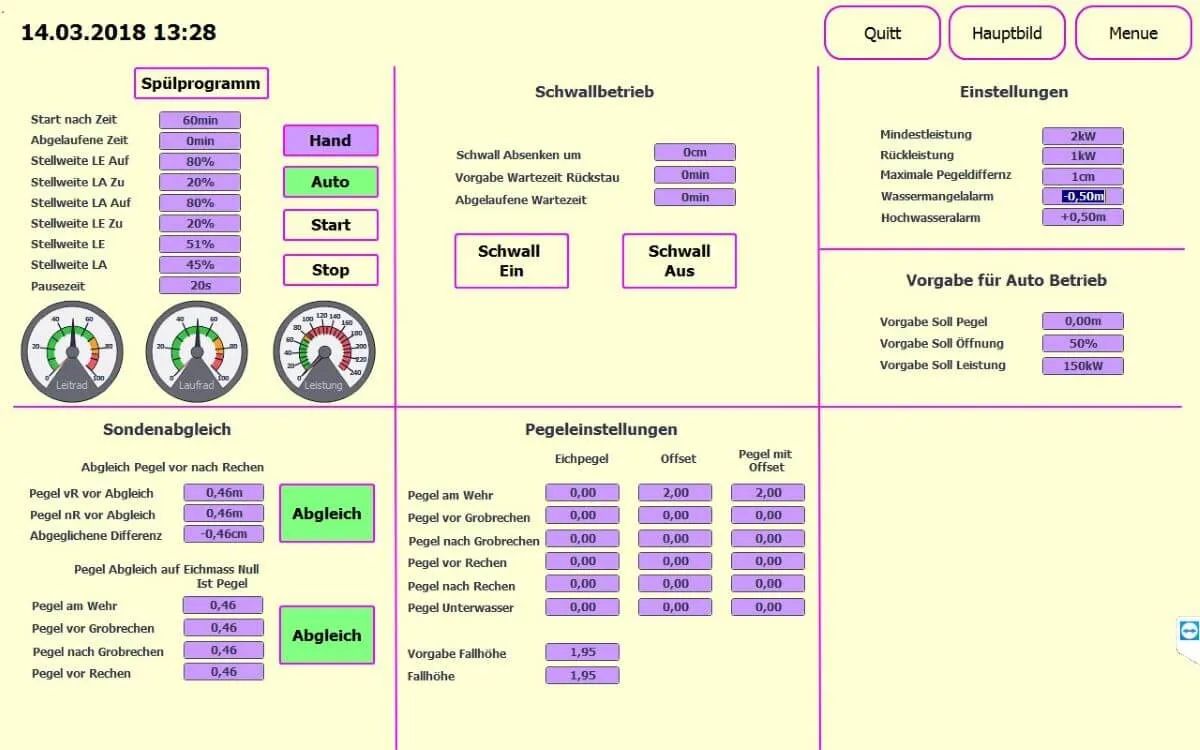

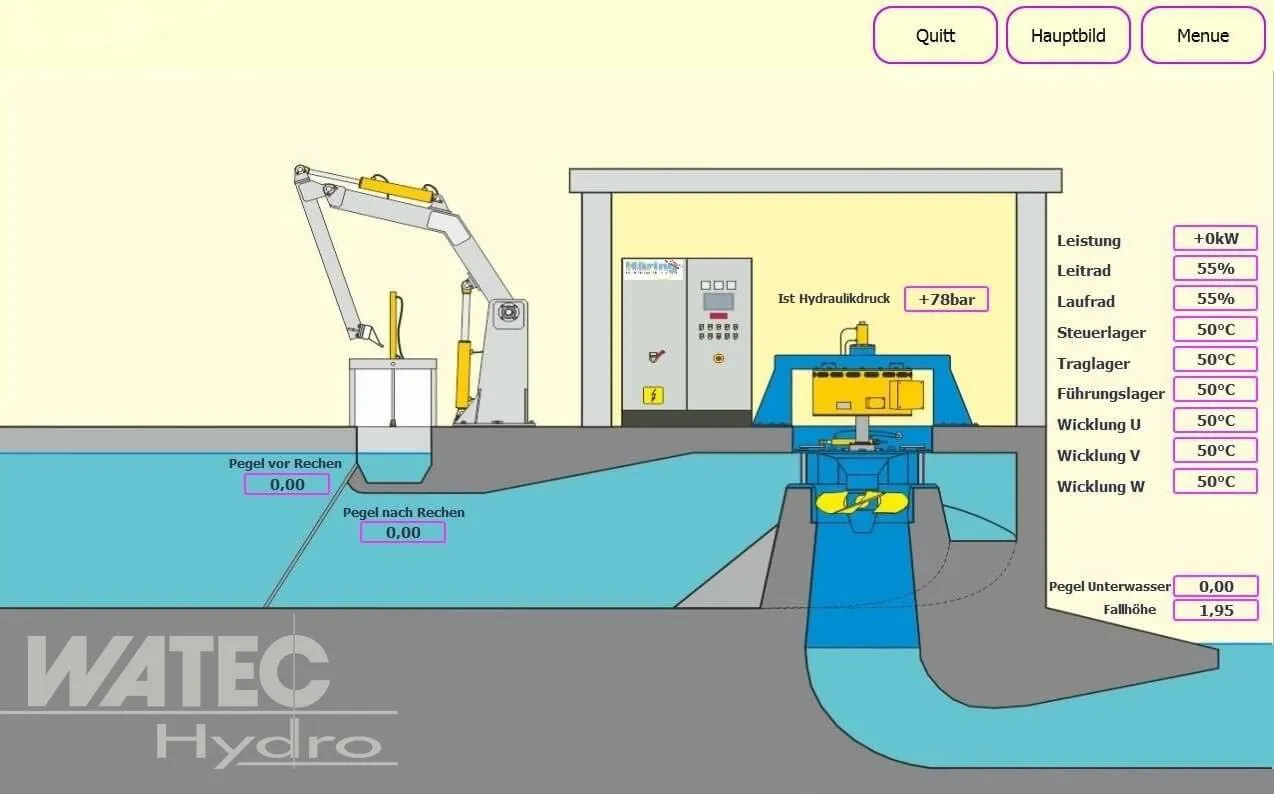

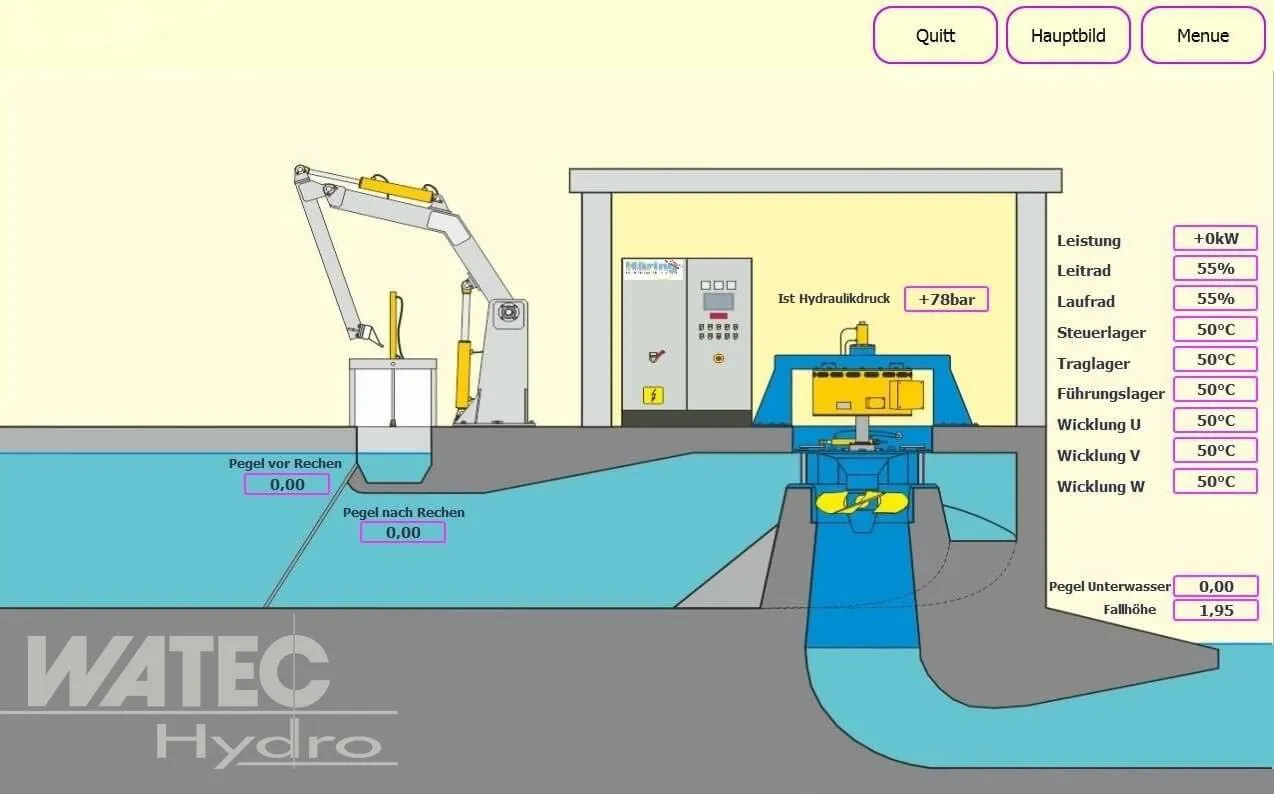

Intuitive user interface

For process visualization, we installed a TP 1200 touch panel from Siemens in our control cabinet.

This is particularly user-friendly, intuitive to use and of high quality.

A logically structured menu guides the user through the individual functions of the control.

All important information and operating elements are clearly arranged and clearly labeled.

If you have any questions, you will find an integrated help function on the spot.

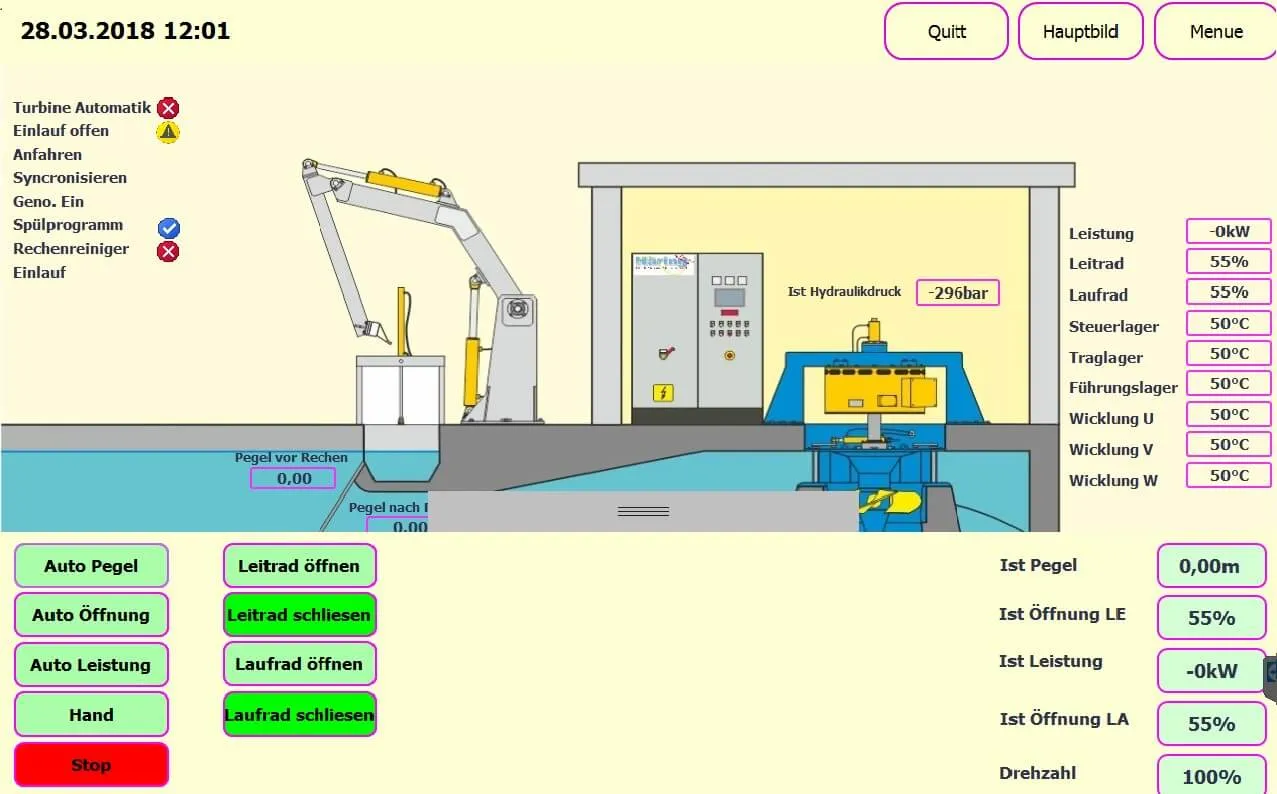

The operating modes of the turbine control

The turbine control is suitable for all types of turbines up to 1MW

The following operating modes are possible:

- - Automatic level, opening and power control

- - Manual operation

The various operating modes can be set quickly and easily via the touch panel.

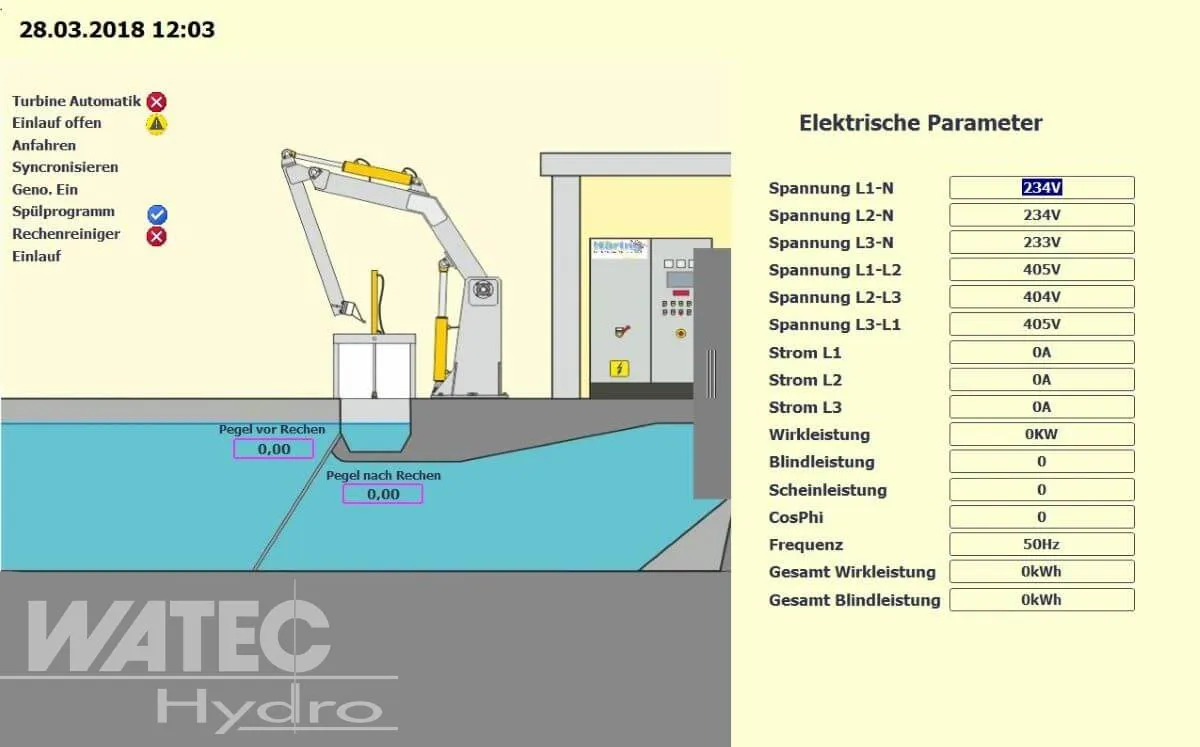

Electrical parameters

The controller measures the electrical parameters and displays them via the touch panel.

The following electrical parameters can be displayed:

- - Voltage

- - Current

- - Active power

- - Reactive power

- - Apparent power

- - CosPhi

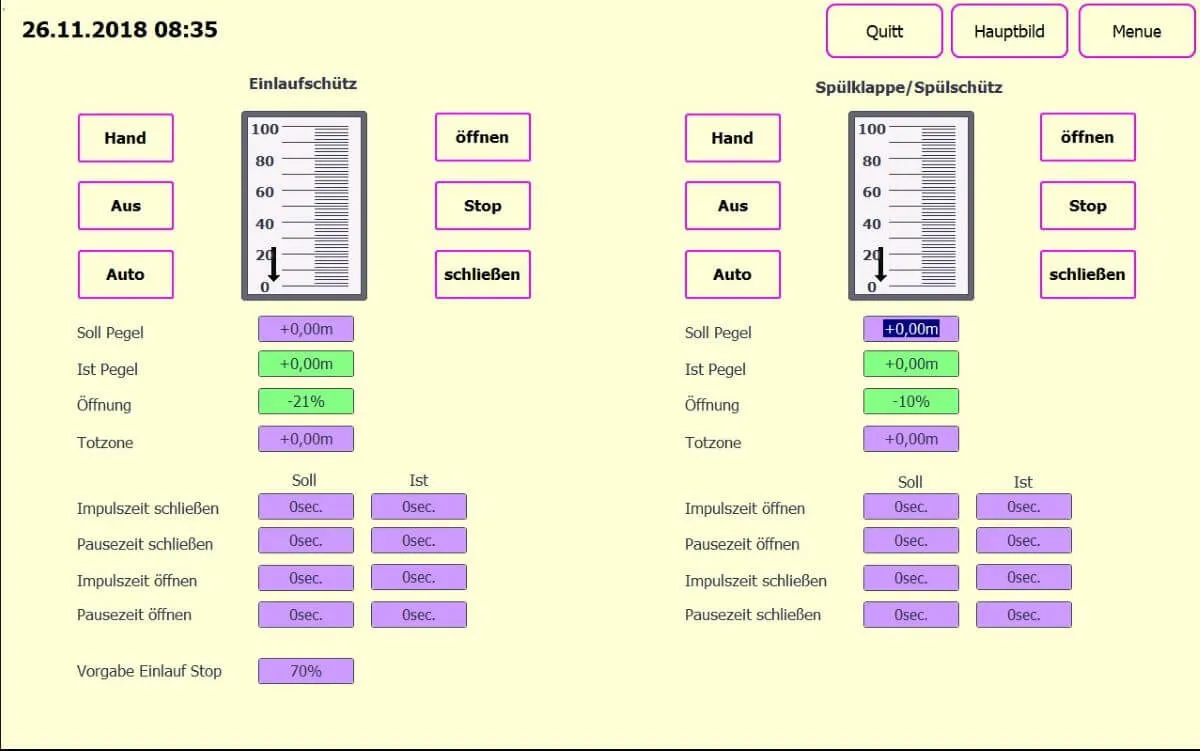

The rinsing program

The flushing program prevents contamination of the turbine's guide vane and impeller.

If more flotsam occurs in the inflow area of the turbine, this reduces the output or can lead to a standstill of the turbine.

The control system periodically starts a process that performs self-cleaning of the turbine.

The flushing program is set in consultation with the turbine manufacturer.

Level control

The level is usually controlled by the measurement of the probe upstream of the rake. If a high volume of floating debris results in an excessively high differential pressure, the turbine automatically switches to differential pressure control.

This prevents suction on the rake and allows the flotsam to be removed by the rake cleaner.

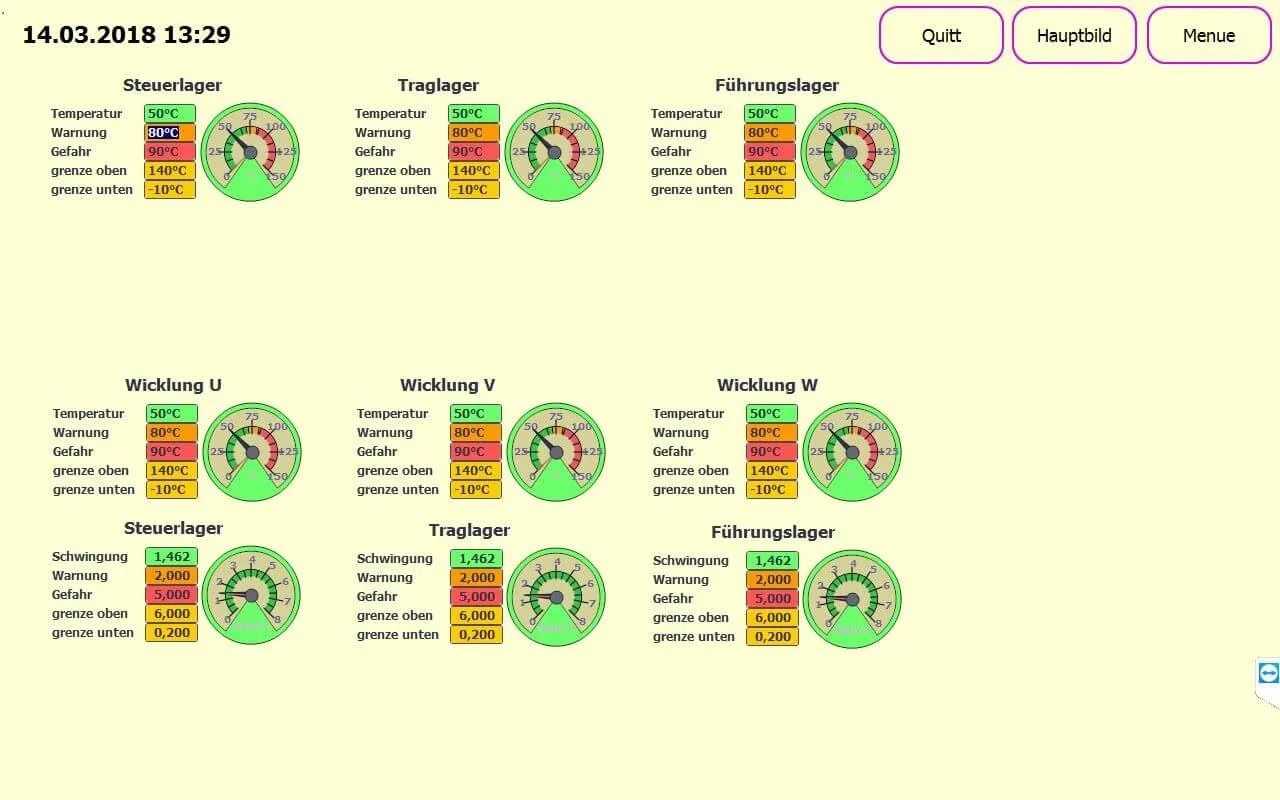

Temperature monitoring

To ensure trouble-free and low-maintenance operation and avoid major damage, it is important to monitor the turbine bearing temperatures and the generator winding temperatures at all times.

See quickly and at a glance all important temperature conditions of your plant.

If certain limit values are exceeded, either a warning message is sent or the turbine is shut down in case of danger.

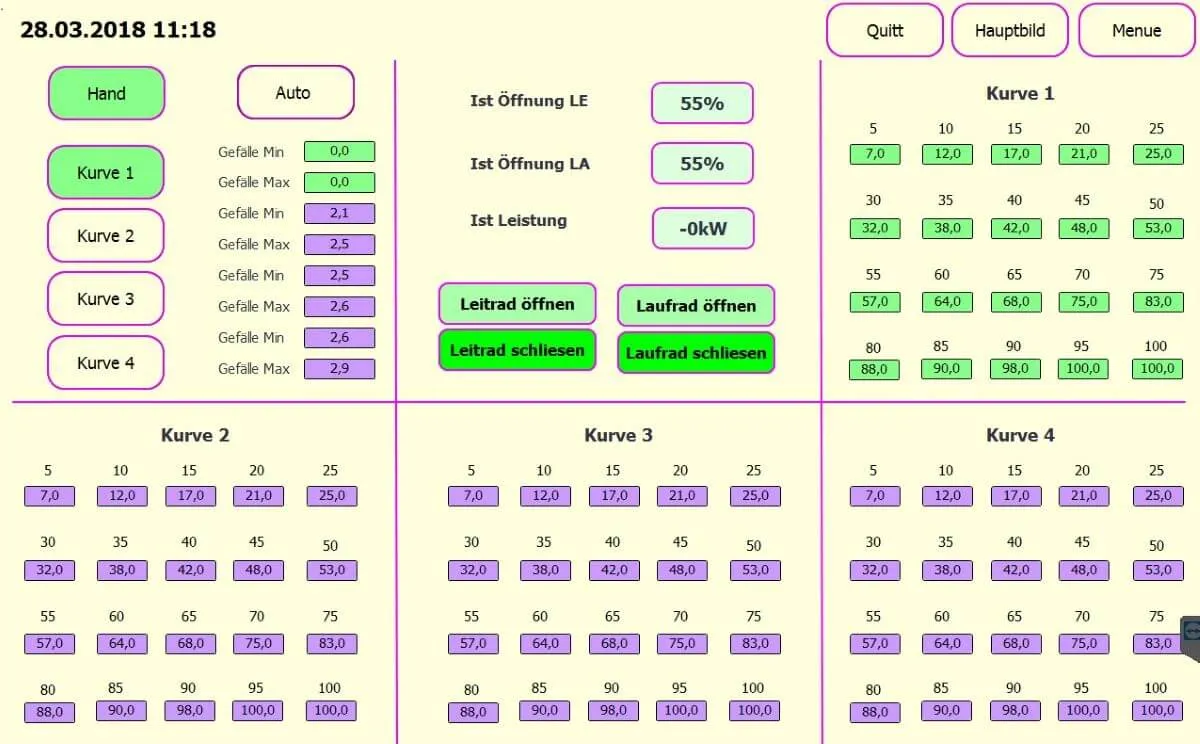

Guide wheel / impeller curve

In the turbine control system, an assignment of the opening position for the guide wheel and impeller curve specified by the manufacturer is stored.

The corresponding guide and impeller curve is set as a function of the drop height.

In order to achieve the optimum performance, the guide vane and runner curve can be adjusted individually, if required, also in consultation with the turbine manufacturer, after commissioning.

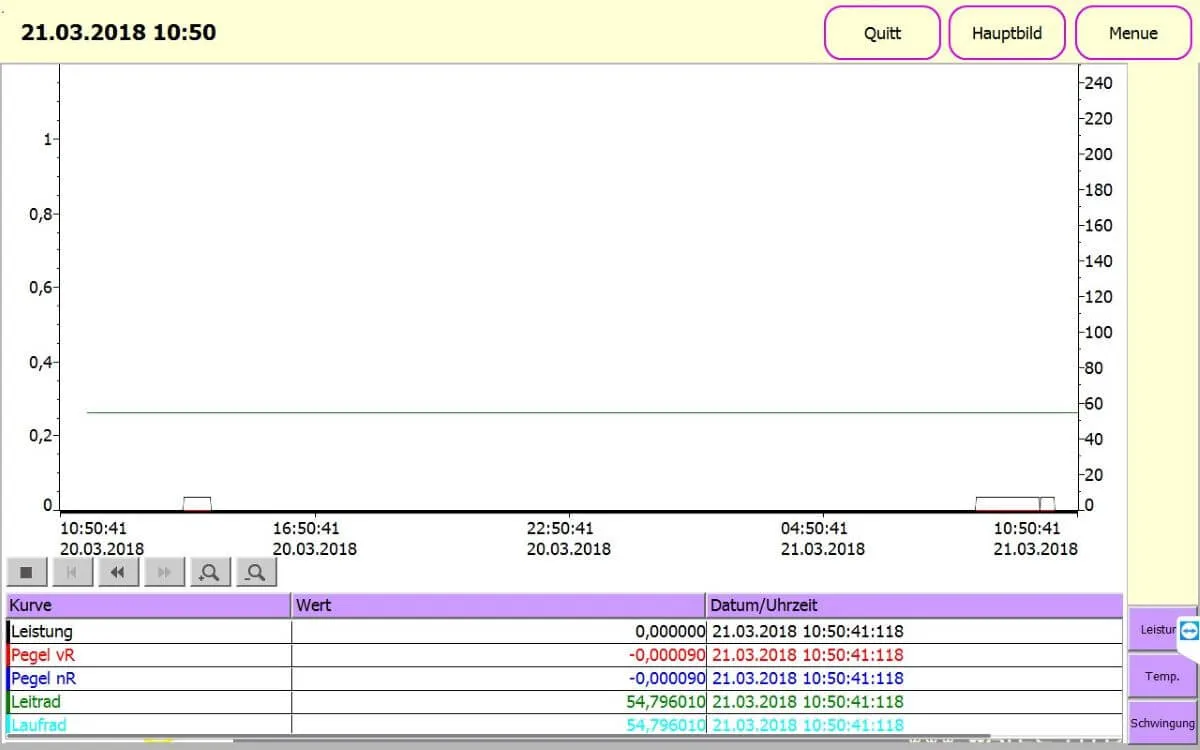

Curve archives

For your own documentation, but also to avoid problems with third parties, the level values and the power values are optionally also stored vibrations and temperatures in a curve archive.

In the curve archive, the course can be traced on the basis of the recorded curves.

The curves can be individually formatted in their display type.

Individual parameters are thus recorded quickly and easily.

Hydraulic steel structures

All steel water components such as screen cleaners, flushing gates, weir panels, fish augers, etc. can be easily integrated into the control system.

These can also be operated via the visualization and the corresponding parameters can be read out.

Existing components can be integrated into a new control system at any time.

Remote access

Of course, it is also possible to set up remote access and alarming in case of malfunctions.

This can be done via the web browser, an app, email or SMS dispatch, depending on your preference.

HCU 4.0 - Our turbine control system